| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,EXW |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 300000pcs per month |

| Packing: | Polybag, Inner Box,... |

| Delivery Date: | Shipped in 30 days... | Power: | Manual |

|---|---|---|---|

| Standard or Nonstandard: | Standard | Pressure: | Medium Pressure |

| Structure: | Stop | Material: | Brass |

| Temperature of Media: | Medium Temperature | Media: | Water |

| Brand Name: | JUNYUAN | SIZE: | 1/2"-1" |

| COLOR: | BRASS OR PLATED | MATERIAL: | BRASS OR BRONZE |

| CERTIFICATE: | ISO9001,UL.CSA,UPC.BS5154, | Connection:: | MALE AND FEMALE |

| Technical:: | FORGED OR CASTING | Working Temperature: | -10℃ to +120℃(from 14°F to 248°F) |

| HS Code: | 8481804090 | FUNCTION: | Suitable for hot and cold water,compressed air,oils, non-corrosive fluids and steam. |

| TECHNICAL: | Forged |

Brass Water Meter Stop Valve with Female and Free Nut

Material :CW617n ,CW617. 614 ,614n .57-3, 59-1 , C37700.C37710.

.Working medium: water oil gas....

.Female/female /male threads,

Body in brass

Seal in EPDM PTEF,

Brass body brass bonnet brass(Iron) stems cast Iron(aluminum) handle

Minimum and maximum working temperatures:

-20°C, 100°C

Threads: ISO 228(equivalent to DIN259 and BS2779)

♦ Size:1/2" 3/4" 1"

• Fire Protection Valve,Threaded Ends,Rubber Disc,Screw Over Bonnet.

• 175 PSI/12.1 Bar Non-Shock Cold Water.

• Threads Standard:IS0 228.

* Thread End: ♦ Product's pic: *Soldering End: *Union End:

♦ Advantage |

| •Prompt Quotation •Punctual Delivery •Honest Reliable Prestige And Elegant Design. |

| •Competitive Price •100% leakage test •Strictly & perfect management is garantee for production |

| •Guaranteed Quality •Sincere service •CE approved.ISO9001 Certificate.etc. |

| •Specialized in manufacturing,supplying a wide range of Bronze&Brass Valves For more than 15years |

| •Have rich experience and strong ability to develop new products. |

| •Have ability to design the products based on your requirement. |

| •The important that Im on line now and u will contact me about the products u need at any time. |

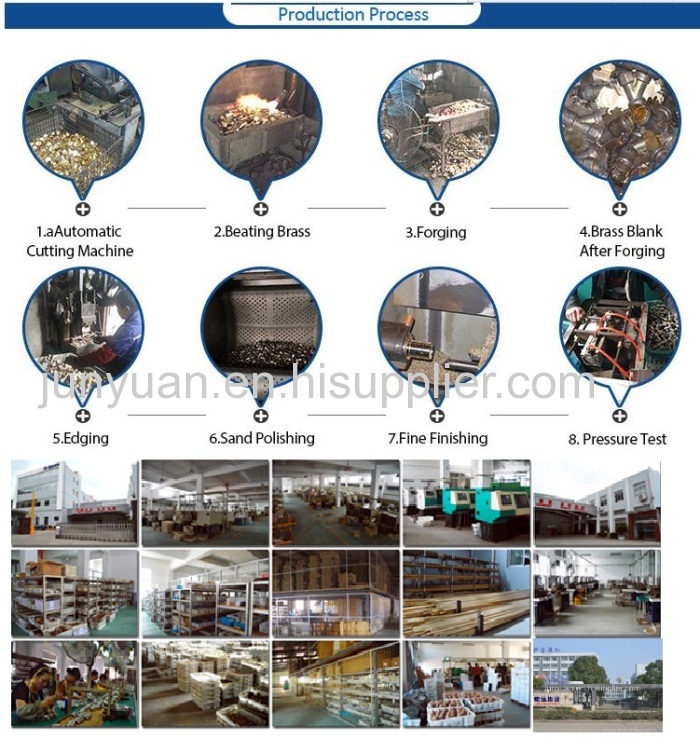

| ♦ Production and inspection step | |||

| 1 | Purchasing the raw material | 10 | PQC inspection |

| 2 | IQC inspection | 11 | Surface treatment |

| 3 | Cutting material | 12 | PQC inspection |

| 4 | PQC inspection | 13 | Assemble parts to full products |

| 5 | Forging parts | 14 | Testing |

| 6 | PQC inspection | 15 | Packing |

| 7 | Sanding or Polishing parts | 16 | OQC inspection |

| 8 | PQC inspection | 17 | Delivering |

| 9 | Machines for processing | 18 | Reorder From Customers |

| ♦ Packaging Detail: | ♦ Delivery Detail: | |||||||

| ♦ International standard Export Packaging: | ♦ 30-45 days after receipt the deposit. | |||||||

| Plastic bag→Inner box→Carton→Pallet. | ||||||||

| ♦ According to Customers' Specific Requirments. | ||||||||

| ♦ Contact Information |