| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 30000PCS/Year |

| Packing: | Valves are wrapped in... |

| Delivery Date: | stock or 15 days | Power: | Others |

|---|---|---|---|

| Standard or Nonstandard: | Standard | Media: | Water |

| Pressure: | Medium Pressure | Material: | Others |

| Temperature of Media: | Others | Structure: | Check |

| Brand Name: | xbvalve | Standard: | ANSI |

| Size: | Dn40~Dn900 | Specification: | DN40-700 |

| HS Code: | 8481804090 | Flow Direction: | Unidirection |

| Application: | Industrial Usage, Water Industrial Usage, Household Usage | Inch: | 1-1/2 "~24" |

| Certificate: | ISO, Ce .API RS | Transport Package: | Export Polywood Case |

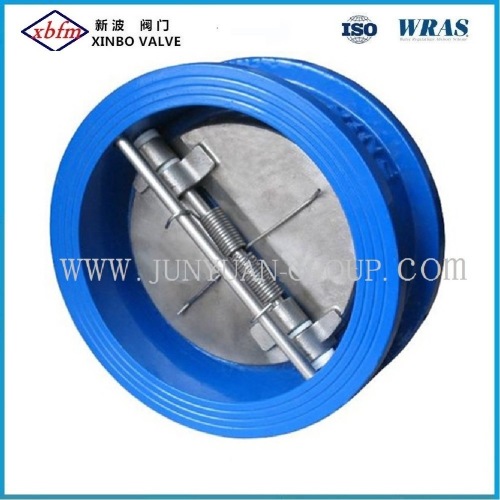

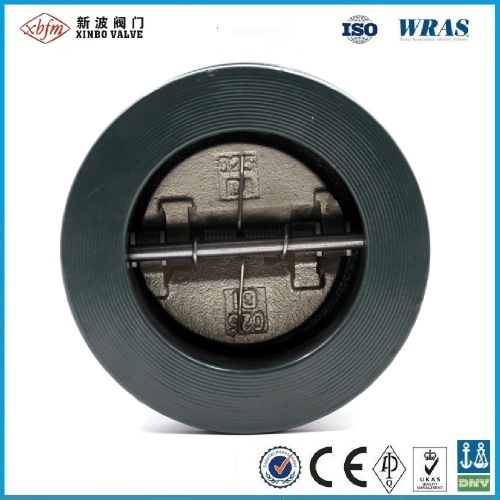

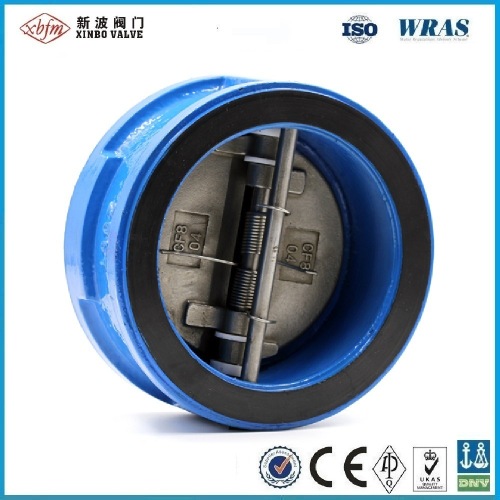

Cast Iron Double Disc Wafer Type Check Valve

Wafer Double Disc Check Valve

Wafer Double Disc Check Valve PN10 PN16 DN50-DN600

PRODUCTION STANDARDS

| Design: API 594 | |||||

| Face to Face Dimension: EN558-Series 20, | |||||

| Flange: EN1092-1 | |||||

| Working Pressure: | PN10 | PN16 | |||

| Shell Test: | 1.5Mpa | 2.4Mpa | |||

| Seat Test | 1.1Mpa | 1.8Mpa | |||

| Application: | Water/ Swage | ||||

| Test Standard | DIN32320/ API 598 | ||||

FEATURES

• The innovative dual-plate design employs two spring-loaded plates suspended on a central vertical hinge as flow begins, the plates open in response to a resultant force Which acts at the center of the sealed surface area

• The contact point of the reacting spring leg's force acts beyond the center of the plate area,causing the heel to pen first.This prevents rubbing of the seal surface prior to normal plate opening

• As the velocity of flow decreases, torsion spring action reacts automatically. The moves of plates closer to the body seats, reducing the distance and time of travel for closure. By Having the plates closer to the body seats at the time of flow reversal.the valve dynamic response is greatly enhanced.This dramatically reduces the water hammer effect

• At closing, the point of spring force causes the plates to close first. This prevents dragging of the heels of the plates and periods maintains seal integrity for much longer periods

APPLICATIONS

Steam, superheated water, hot water, cold water, fluids without acidity or alkalinity properties,chemicals

TEMPERATURE

+200 °C

Other products

Why Choose US

Why Choose US

Our factory is specialized in valves' production. As one of the biggest and most professional manufacturer and exporter majored in valves, we assure that we can provide our products with cheapest price, good quality and best service. If you like, welcome to our factory and have a look!

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Contact to this supplier

Category: CAST IRON CHECK VALVE

Related Category: BRONZE CHECK VALVE BRASS CHECK VALVE DUCUILE IRON CHECK VALVE STAINLESS STEEL CHECK VALVE